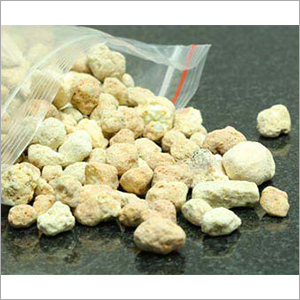

Dead Burnt Magnesite - Turkey Origin

Price 38500.00 INR/ Ton

Dead Burnt Magnesite - Turkey Origin Specification

- Surface Finish

- Rough

- Purity(%)

- 90% min

- Form

- Lumps

- Usage & Applications

- Used in refractory lining for steel furnaces, cement and non-ferrous industries

- Hardness (%)

- Mohs 5.5-6.0

- Chemical Composition

- MgO: 90% min, SiO2: 1.5% max, CaO: 3.0% max, Fe2O3: 1.5% max, Al2O3: 0.5% max

- Density

- 3.30 Gram per cubic centimeter(g/cm3)

- Water Absorption

- Negligible

- Melting Point

- 2800C

- Application

- Steel, Chemical & Glass Industries

- Product Type

- Dead Burnt Magnesite

- Types of Refractories

- Other

- Shape

- Other

- Porosity

- 14-16%

- Dimensional Stability

- Excellent at high temperature

- Strength

- High

- Specific Gravity

- 3.3 g/cm

- Thermal Conductivity

- Low

- Color

- Brownish Grey

- Storage Condition

- Dry & Covered Place

- Packaging Type

- Bulk, 1 MT Jumbo Bags

- HS Code

- 251990

- Bulk Density

- 2.95-3.10 g/cm³

- Grain Size

- 0-50 mm, customizable

- Loss on Ignition (LOI)

- 1.5% max

Dead Burnt Magnesite - Turkey Origin Trade Information

- Minimum Order Quantity

- 1 Ton

- Supply Ability

- 3000 Tons Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Australia, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia, North America

- Main Domestic Market

- All India

About Dead Burnt Magnesite - Turkey Origin

Dead Burnt Magnesite (DBM) is manufacturer by sintering Cryp to Crystalline Magnesite Ore in Rotary Kiln at a controlled temperature between 1750-1800 Degree Centigrade. Turkish Dead Burnt Magnesite is chemically inert and extremely heat resistant. Turkish DBM has unique characteristics of low Iron content below 0.3%, which makes it most ideal Raw Material for Induction Furnace Ramming Mass.

Industrial Minerals & Refractories holds exclusive agency of M/s Konyakrom,Turkey which is Turkeys most reputed Dead Burnt Magnesite manufacturer located in Konya,Turkey. Konya region hosts Turkeys purest Magnesite Deposits with low Iron content unlike Kutahya Deposits, which imparts white texture to DBM just like high grades (ie.MgO 90% and above) of Indian Dead Burnt Magnesite. Konyakrom do not demand long term contracts unlike other Turkey suppliers, which gives flexibility to buyer to decide his procurement planning as per their choice to avoid excess inventory and procure only when they want and need.

Konya krom Dead Burnt Magnesite can be booked directly to buyer from Konyakrom or can also be available from our Salem Warehouses or under Delivery Duty Paid basis under GST Billing from nearest Sea Port to you.

Specification

Chinese Dead Burnt Magnesite

| TYPICAL CHEMICAL ANALYSIS | |||||||

|---|---|---|---|---|---|---|---|

| Grades | MgO | SiO2 | Fe2O3 | CaO | Al2O3 | LOI | BD (g/cm3) |

| DBM 90 (H) | 90% | 4.50% | 1.50% | 2% | 0.80% | 0.50% | 3.1 |

| DBM 90 (D) | 90% | 4.50% | 1.80% | 3% | 1.50% | 0.70% | 3.05-3.1 |

| DBM 92 (B) | 92% | 4% | 1.80% | 1.80% | 0.40% | 0.50% | 3.10% |

| DBM 92 (M) | 92% | 3.80% | 1.50% | 1.80% | 0.40% | 0.30% | 3.15 |

| DBM 95 | 95% | 2.10% | 80.00% | 1.40% | 0.30% | 20.00% | 3.2 |

| Coarse Sizes | 1-15 mm, 3-15 mm, 5-15 mm, 3-8 mm, 5-10 mm (High Bulk Density Fractions) | ||

| Small Fractions | 0-1 mm,0.5-1 mm, 1-3 mm, 1-5 mm, #200 mesh (Low Bulk Density Fractions) | ||

| Packing | 1.35 MT Big Bags or 50 kg Bags into 1.25 MT Big Bags | ||

| Colour | Brown | Origin | China |

DEAD BURNT MAGNESITE FROM KONYAKROM, TURKEY

| TYPICAL CHEMICAL ANALYSIS | |||||||

|---|---|---|---|---|---|---|---|

| Grades | MgO | SiO2 | Fe2O3 | CaO | Al2O3 | LOI | BD (g/cm3) |

| KSKM 85 | 85.0% | 11.0% | 0.5% | 3.0% | 0.5% | 0.2% | 3.25 |

| KSKM 87 | 87.0% | 9.5% | 0.5% | 3.0% | 0.5% | 0.2% | 3.25 |

| KSKM 90 | 90% | 6.0% | 0.5% | 3.0% | 0.5% | 0.2% | 3.3 |

| KSKM 91 | 91.0% | 5.0% | 0.5% | 3.0% | 0.5% | 0.2% | 3.3 |

| KSKM 92 | 92.0% | 4.5% | 0.5% | 3.0% | 0.5% | 0.2% | 3.3 |

| KSKM 93 | 93.0% | 5.0% | 0.5% | 2.0% | 0.5% | 0.2% | 3.35 |

| KSKM 93.5 | 93.5% | 4.0% | 0.5% | 2.5% | 0.5% | 0.2% | 3.4 |

| KSKM 95 | 95% | 1.5% | 0.5% | 2% | 0.2% | 0.2% | 3.4 |

| KSKM 96 | 96% | 1% | 0.5% | 1.8% | 0.2% | 0.2% | 3.4 |

| KSKM 96.5 | 96.5% | 0.8% | 0.5% | 1.7% | 0.2% | 0.2% | 3.45 |

| Fraction Size | 0-15 mm Standard Size for all Grades | ||

| Small Fractions | 0-1 mm, 1-3 mm, 3-5 mm, 1-5 mm, #200 mesh | ||

| Packing | 1.35 MT Big Bags | ||

| Colour | Yellow to White | Origin | Turkey |

Indian Dead Burnt Magnesite

| Grades | MgO(Min) % | CaO(Max) % | Al2O3(Max) % | Fe2O3(Max) % | SiO2(Max) % | LOI(Max) % | Bulk Density |

| I | 90.00 | 1.50 | 0.50 | 1.00 | 6.50 | 0.50 | 3.4 |

| II | 89.00 | 1.50 | 0.50 | 1.00 | 7.50 | 0.50 | 3.4 |

| III | 88.00 | 1.50 | 0.50 | 1.00 | 8.50 | 0.50 | 3.4 |

| IV | 87.00 | 1.50 | 0.50 | 1.00 | 9.50 | 0.50 | 3.3 |

| V | 86.00 | 1.75 | 0.75 | 1.50 | 11.00 | 0.50 | 3.25 |

| Coarse Sizes | 0-15 mm, #44 mesh, #100 mesh, #200 mesh, #325 mesh | ||

| Packing | 25 or 50 kg HDPE or Paper Bags & Big Bags | ||

| Colour | Yellow to White | Origin | India |

Superior Refractory Properties

With a high MgO content (min 90%), dead burnt magnesite exhibits excellent resistance to heat, chemical attack, and mechanical stress. Its impressive melting point of 2800C and low porosity make it especially suitable for steel furnace linings and other high-temperature industrial applications.

Versatile Applications

This product is utilized extensively in steel, cement, and non-ferrous industries. Its outstanding strength and dimensional stability at elevated temperatures enhance the durability and efficiency of furnaces, kilns, and other high-heat environments where refractory lining is crucial.

FAQs of Dead Burnt Magnesite - Turkey Origin:

Q: How is Dead Burnt Magnesite from Turkey typically packaged for shipment?

A: Dead Burnt Magnesite is available in bulk or packaged in 1 MT jumbo bags. Custom packaging options are also offered to suit specific logistical or handling requirements.Q: What industries primarily utilize Dead Burnt Magnesite and why?

A: Steel, chemical, and glass industries are the main users of Dead Burnt Magnesite due to its high purity, excellent heat resistance, and reliability as a refractory lining material for furnaces and kilns.Q: When is Dead Burnt Magnesite recommended over other refractory materials?

A: It is recommended when high-temperature stability, chemical inertness, and minimal water absorption are crucialspecifically in steel-making furnaces, cement plants, and applications requiring low porosity and high strength.Q: Where should Dead Burnt Magnesite be stored to maintain quality?

A: It should be kept in a dry, covered place to prevent moisture absorption and preserve its physical and chemical properties.Q: What is the process involved in customizing the grain size of Dead Burnt Magnesite?

A: Grain size for Dead Burnt Magnesite (range: 0-50 mm) can be tailored during production or post-crushing, based on customer requirements, ensuring it meets specific application demands.Q: How does Dead Burnt Magnesite benefit refractory linings in steel furnaces?

A: Dead Burnt Magnesite provides exceptional dimensional stability, low thermal conductivity, and high mechanical strength, enhancing the service life and efficiency of steel furnace linings.Q: What are the key advantages of using Dead Burnt Magnesite in industrial processes?

A: Key benefits include superior heat tolerance, chemical resistance, low porosity, and excellent performance under extreme conditions, making it a preferred choice for demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dead Burnt Magnesite Category

Dead Burned Magnesite - Chinese Origin

Price 19000 INR / Ton

Minimum Order Quantity : 27 MT from Port or 5 MT from Salem. Tons

Usage & Applications : Manufacturing of basic refractory bricks, furnace lining, steel making

Surface Finish : Granular

Dimensional Stability : Other, Excellent at high temperatures

Purity(%) : >90

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS